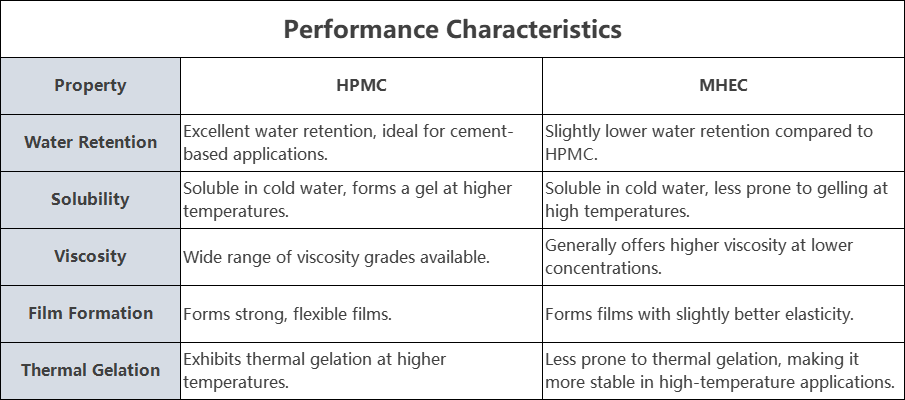

Cellulose ethers are versatile additives widely used in construction, pharmaceuticals, personal care, and food industries. Among the most popular types are Hydroxypropyl Methyl Cellulose (HPMC) and Methyl Hydroxyethyl Cellulose (MHEC). While both are derived from cellulose and share some similarities, they have distinct performance characteristics, application areas, and advantages.

Advantages and Disadvantages

HPMC

- Advantages:

Excellent water retention, making it ideal for construction applications.

Wide range of viscosity options for diverse applications.

Strong film-forming properties.

Cost-effective and widely available.

- Disadvantages:

Prone to thermal gelation, which can limit its use in high-temperature environments.

Slightly less elastic films compared to MHEC.

MHEC

- Advantages:

Better workability and spreadability in construction applications.

Higher viscosity at lower concentrations, reducing the required dosage.

More stable at high temperatures, making it suitable for exterior applications.

Provides smoother and more elastic films.

- Disadvantages:

Slightly higher cost compared to HPMC.

Lower water retention, which may not be suitable for all construction applications.

How to Choose Between HPMC and MHEC

- For Construction Applications:

- Choose HPMC if you need high water retention for cement-based products like tile adhesives or self-leveling compounds.

- Opt for MHEC if you require better workability and stability in exterior insulation systems or plasters.

- For Pharmaceuticals and Personal Care:

- HPMC is the preferred choice for tablet binders and controlled-release formulations.

- MHEC is better suited for skincare products where sensory properties are important.

- For Food Applications:

- HPMC is more commonly used as a thickener and stabilizer in food products.

- MHEC is less common in food but can be used in specific formulations requiring higher viscosity.

Conclusion

Both HPMC and MHEC are high-performance cellulose ethers with unique properties that make them suitable for different applications. HPMC excels in water retention and cost-effectiveness, making it ideal for construction and pharmaceuticals. On the other hand, MHEC offers better workability, thermal stability, and elasticity, making it a preferred choice for exterior construction and personal care products.

By understanding the performance characteristics, application areas, and advantages of each, you can make an informed decision and select the right cellulose ether for your specific needs. Whether you choose HPMC or MHEC, both products offer exceptional quality and versatility for a wide range of industries.